Increase your profits by using the VisiGrader to grade lobsters.

Now, one person can grade lobsters ...

... just as fast as two people using the traditional method.

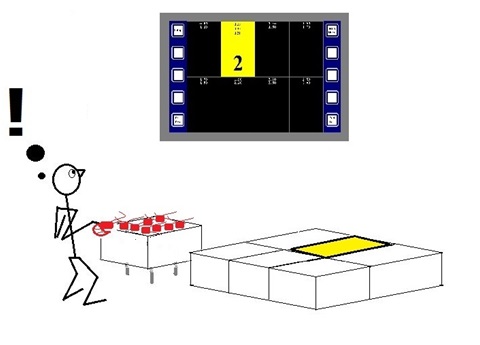

A crate of lobsters is placed on the scale. As each lobster is removed from the crate, the Visual Sorter instantly indicates by color and number which destination crate the lobster should be placed in.

The grading station operator simply observes the color or number and places the lobster in the crate associated with that color or number.

Lobster processors find that using the VisiGrader increases profits by

- improving grading accuracy,

- making it easier for new workers to learn how to grade lobsters,

- improving labor efficiency,

- reducing lobster stress and

- reducing worker stress,

... resulting in a happier work environment.

Accuracy

Grading by color or number is easier and more accurate than grading by digital weight alone.

Detecting color or crate number only involves the eyes while converting a digital weight to a particular destination crate engages the whole brain. Fatigue develops due to the repetitive nature of the task. Experienced operators find that color or number grading is less tiring, resulting in fewer mistakes in grading and better product quality.

Shifting the grading weight ranges can be especially confusing digital weight grading, as the mind has to learn to use a new set of weight values.

Ease of Use

New or inexperienced employees find it is much easier to learn to grade lobsters using the color/number system.

Side-by-side tests have shown that employees with 1 hour training on the VisiGrader can grade lobsters as fast and as accurately as employees with years of experience using the old traditional method.

This makes it easier to find workers to perform the grading task.

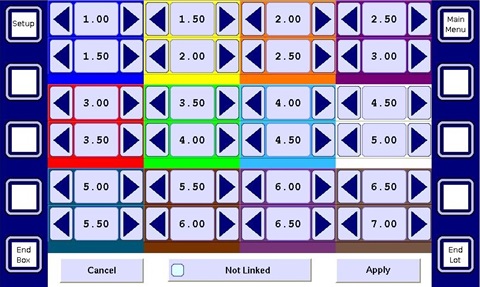

Changing Grade Weights

Different customers may have differing grade requirements.

With the VisiGrader, changing weight grades is simplified. Different weight ranges can be saved, identified by customer name. A customer name can be selected and the VisiGrader is instantly changed to the new weight ranges. This assigns a new set of weight ranges to the different crate colors or crate numbers.

Hundreds of custom weight ranges can be stored on the VisiGrader under different customer names.

For the operator the process remains the same as before: all lobsters that show green (or crate 3) go in the green crate (or crate 3). Those that show blue (or crate 5) go in the blue crate (or crate 5). And so on...

The result is more accurate grading, reduced costs, happier customers and happier employees.

Speed and Productivity

Using the VisiGrader, one person can grade lobsters about as fast as two people using the old, traditional method.

With the VisiGrader, a crate of lobsters is placed on the digital scale.

Only one operator is required

As each lobster is removed from the supply crate, the VisiGrader screen instantly indicates by color or crate number, which destination crate the lobster should be placed in. The person grading simply observes the color or crate number and places the lobster in the correct crate. This cuts labor costs by half.

Lobster grading the old traditional way involves two people and a digital scale. One person removes a lobster from the supply crate and places it on the digital scale. The other person reads the weight on the scale, removes the lobster from the scale and places it in one of several destination crates, depending on the weight of the lobster.

Tests have shown that labor productivity (pounds of lobsters graded per man-hour) improves by 90 – 100 %.

Reduced Lobster Stress

If a lobster doesn't make it to market for whatever reason, then that's revenue that is lost.

Lobsters, despite their seemingly fierce exterior, can be hurt during handling. The very act of handling itself, creates trumatic stress in a wild-caught lobster. This can make healthy lobsters more susceptable to shipping mortality - lobsters that die during transit to markets.

If a lobster dies, the lobster cannot be processed. You cannot cook a dead lobster. You have to throw it out for health reasons.

The traditional 2-person grading method requires that each lobster be handled twice - once to place the lobster on the scale, and again to take the lobster from the scale and place it in the destination crate.

Using the 1-person VisiGrader, lobsters are handled only once, as they are removed from the supply crate and placed in the destination crate.

This cuts handling stress in half, reducing losses due to 'shrink' during shipping.

Cost Savings

If you are using two workers per scale, you will grade about 10 crates of lobsters per hour. At a pay rate of $15 per hour, the cost will be $30.00, or $3.00 per crate.

Using the VisiGrader with one worker per scale, one person will grade 9 to 10 crates per hour. At a pay rate of $15 per hour grading 9 crates per hour, the cost will be $1.67 per crate.

Profits are increased by $1.33 per crate - a 45% saving.

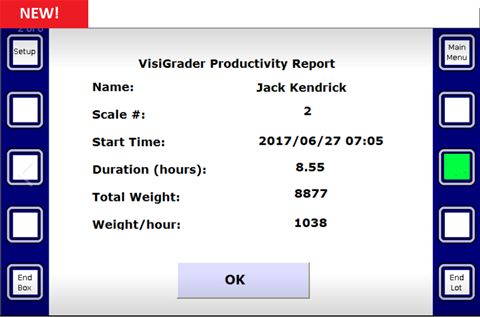

Grading Productivity Report

Management Report showing the total weight of lobsters graded during the shift and the weight graded per hour.

This option can be turned ON or OFF.

We store a copy of the Productivity Reports internally, so you can scroll back through the daily report history at any time.

This information and the

details behind it, can also be sent to a computer file or to a network port in a more advanced setup.

What is the VisiGrader?

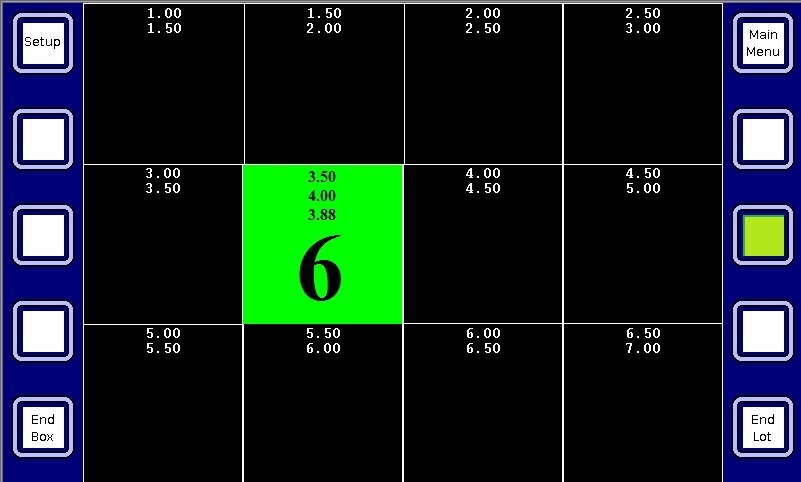

The VisiGrader is a screen display used to simplify the grading of lobsters by using color or crate number to indicate the destination crate. Operators can grade by color or crate number. When a lobster is placed on or removed from a digital scale, a color or crate number appears to indicate which destination crate to place the lobster in. There can be 8 or 12 destination crates.

Using colors, each crate is assigned 1 of 8 or 12 colors, corresponding to the weight range for the crate. All lobsters that show green go in the green crate. Those that show blue go in the blue crate and so on...

Using crate numbers, each crate is assigned a number from 1 to 8 or 12. All lobsters that show "2" go in crate 2. Those that show "5" go in crate 5 and so on...

How does it work?

With the VisiGrader, a crate of lobsters is placed on the digital scale.

Only one operator is required.

As each lobster is removed from the crate, the VisiGrader instantly indicates by color or number which destination crate the lobster should be placed in. The person grading simply observes the color or number and places the lobster in the correct crate.

Thus one person can grade lobsters almost as fast as two people.

Changing Grade Weights

The weight ranges for each color or crate number are programmed using the built-in touchscreen.

Different customers may have differing grade requirements. Different weight ranges can be saved and identified by customer name. A new set of weights can be selected by customer name.

For the operator the process is the same as before: all lobsters that show green (or crate 3) go in the green crate (or crate 3). Those that show blue (or crate 5) go in the blue crate (or crate 5). And so on...

Hooking it up

The VisiGrader works with existing scales with a printer connection. The scale is connected to the VisiGrader by a cable to the printer port. The digital scales continue to operate normally.

VisiGrader is left on all the time to avoid damage by the cold, wet conditions in most grading rooms.

Where to buy the VisiGrader?

We serve Eastern Canada and the Northeastern USA directly.

Know Tech Environmental Inc

201 - 49 Kaulback St.

Truro, Nova Scotia B2N 0B7

Phone: 800-890-8608

or 902 897 5897

email: sales 'at' visigrader.com